1939(Establishment)Kuon Chen Iron Works Co., Ltd. was founded on Linsen N. Rd. (originally named Miyamae-cho) in Taipei City with an area of 2,160 square feet; business items included lathe turning work and mechanical repair.

1948 (Expansion)Renamed Kuon Chen Hardware Factory and expanded to 9,000 square feet; manufactured aluminum plates and utensils.

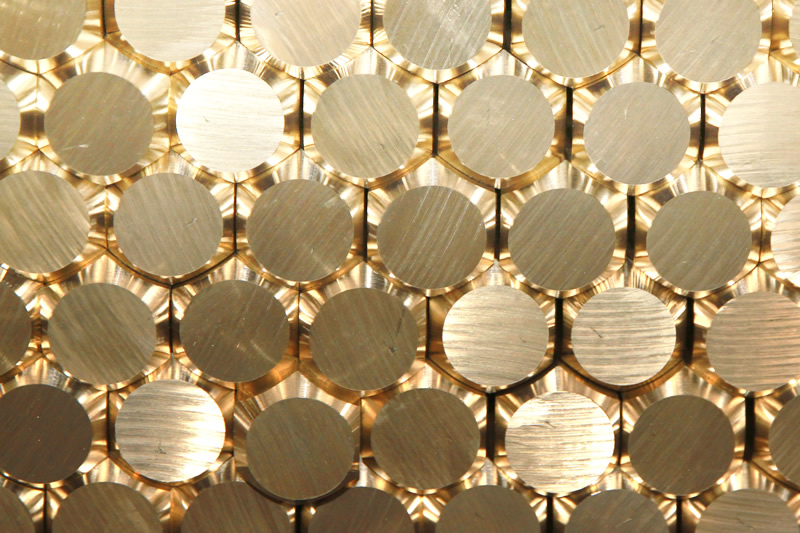

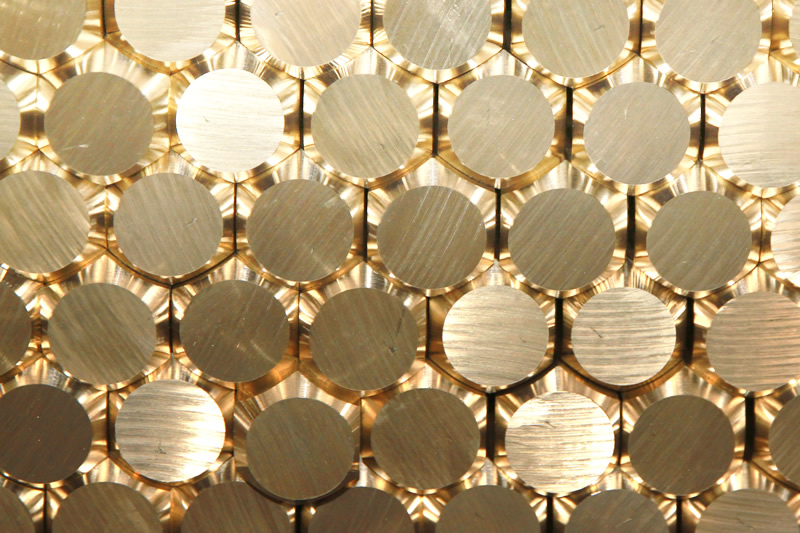

1953Began manufacturing brass plates.

1955Stopped production of aluminum plates and only manufactured brass plates.

1964Purchased a 300 ton extrusion press for manufacturing brass plates and rods.

1969 (Relocation)Renamed Kuon Chen Hardware Ltd. and relocated to Luzhou Township of Taipei County with an area of 43,200 square feet; purchased a 600 ton press for manufacturing brass plates and rods.

1977Renamed Kuon Chen Hardware Co., Ltd. with a capital of NT$26 million; made a 1,000 ton press for manufacturing brass plates and rods.

1979 (Relocation)Relocated to No.24, Dinghu 1st St., Gueishan Township, Taoyuan County (in the fourth industrial zone in Linkou). Stopped producing brass plates; increased capital to NT$40 million, area increased to over 360 thousand square feet and specialized in manufacturing of brass rods and wires.

1983Purchased a high-frequency induction furnace, one vertical casting machine, and one Japanese combined drawing machine.

1985Purchased a horizontal casting line, and a low frequency induction furnace; made a 2,000 ton press.

1988Purchased a 2,450 ton Japanese press and increased monthly capacity to 2,000 tons.

1989Purchased a German combined drawing machine and strapping machine made in Germany.

1990Increased capital to NT$112 million and purchased a combined drawing machine made in Japan.

1991Purchased an German automatic chamfering machine and a Japanese automatic chamfering machine.

1993Purchased a Japanese high speed combined drawing machine for small rods.

1995Purchased an imported large melting furnace and increased monthly capacity to 3,000 tons.

2000Expanded the factory by building a new building at the original site.

2001Purchased a new casting line made in Germany.

2004Purchased 2 imported combined drawing machines; and an imported new extrusion line started production; monthly capacity increased to 5,000 tons.

2005Purchased a large combined drawing machine and imported eddy-current flaw detector for rods.

2006Purchased a new melting furnace and installed new dust-collecting equipment.

2007Purchased a new German casting line

2008Passed the ISO 9001 certification

2014Purchased an imported large 2-roll straightening machine