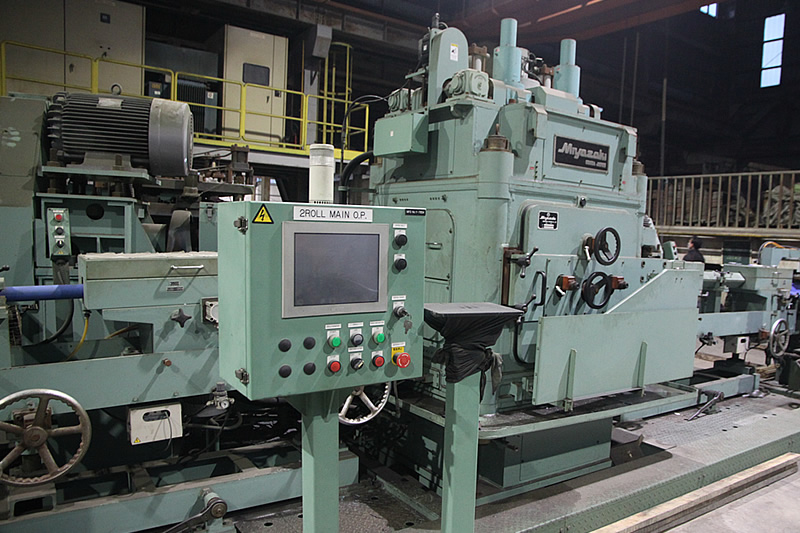

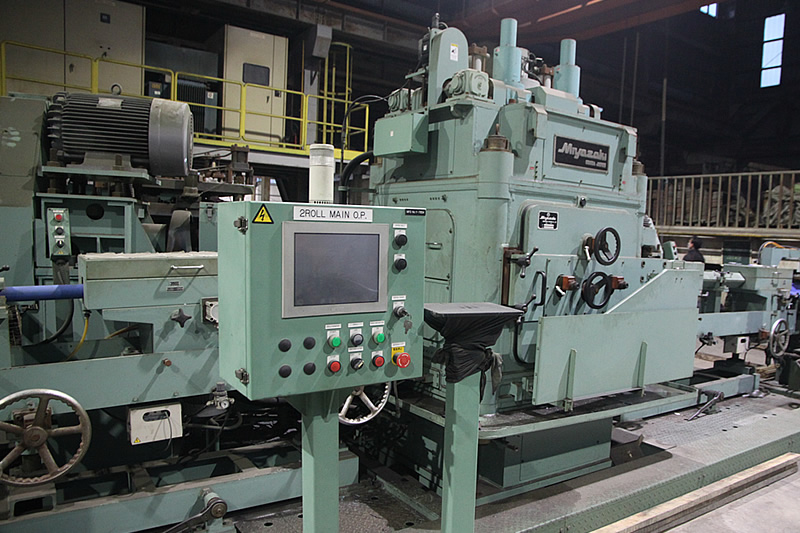

Kuon Chen Hardware Co., Ltd. was founded in 1939, and started off as an iron works company, shifting to aluminum plates and utensils and further on to brass plates. We began producing brass extrusions in 1964, and have accumulated over fifty years of experience in manufacturing brass rods, brass extrusions and brass wires. Our production process is as follows: we first melt raw materials using a low-frequency induction furnace and adjust the alloy composition, and then use our continuous fully automatic casting machine to make billets. The microstructure of billets is homogeneous without any dirt holes or defects. All alloys we produce comply with international standards, including JIS, ASTM, CNS, DIN, and BS. The billets are heated and then extruded into coils by our state-of-the-art extrusion press. Coils went through drawing and annealing processes, and then made into rods and wires by over 20 combined drawing machines either made in Germany or Japan. Every link in the production process is strictly monitored by our quality management system to ensure that every rod and wire meets specifications. We have always upheld the principles of honesty and trustworthy when serving our clients, and it has allowed our business to grow along with our clientele. Thanks to the recognition by clients and confidence in our products, we have become the market leader in brass rods and wires in Taiwan for decades. Our products are exported to Japan, Southeast Asian countries, and China, and we have gained certifications and the approval of overseas clients.

Kuon Chen Hardware Co., Ltd. has been very active and creative in the over seventy years since it was established, constantly improving processes for making top-notch brass rods and wires with an outer diameter ranging from Ø1.5 to Ø65 mm, diameter tolerance under 0.3%, good straightness, and smooth surface. Hexagonal, square, and brass profiles are also important products widely adopted for lathe machining. We are actively working with clients in research on alloys with respect to machinability and increasing cutting efficiency. We have developed dozens of alloys and make recommendations based on the processing method and requirements of our clients, allowing them to increase their cutting speed, extend the lifespan of their cutting tools, increase precision of work pieces, and increase production and yield, which all contribute to the ultimate objective of lower cost for our clients.

Quality, Innovation, Eco-friendly, Sustainability

Our products can be divided into brass rods, free-cutting brass rods, forging brass rods, brass extrusions, brass profiles, and brass wires. Brass rods can be used to make automobile components, tire valves, electronic appliances and 3C products, precision parts, fittings, connectors, screws, clock or watch components, mechanical parts, gas appliances, water ware components, bicycle parts, locks, pens, and plugs. Brass wires can be used for making bicycle or motorcycle spoke nipple, clock or watch components, small screws, plugs, precision parts, electronic appliances and 3C parts, connectors, pins, and mechanical parts.

At present, Kuon Chen Hardware Co., Ltd. is located in the fourth industrial zone in Linkou, Taoyuan City and covers an area of over 33,000 square meters. Even though we have enjoyed a reputation in the hardware industry for over 70 years and are one of the largest manufacturers of brass rods and wires in Taiwan, we have tirelessly devoted great efforts to improving our production processes in response to changes in the market and to meet requirements of our clients. This has enabled our products remain popular in Taiwan and overseas throughout the years. In the future, we will continue to seek improvement and fulfill our corporate social responsibility to achieve sustainable development and contribute to social welfare.

Copper is a recyclable metal, and the alloys we produce are the same. In addition to electrolytic refined materials, we select and acquire high grade copper scraps and customers’ machining scraps, processed, analyzed, melted, and formulated into quality alloys complying with international standards. We have been devoted ourselves in reuse and recycle of limited resources in our planet.

As a member of Earth, we have always attached great importance to environmental protection based on the concept of sustainable development. All waste gas and water emissions go through proper treatment by qualified equipment and meet the government’s emission standards. In recent years, we have focused on reducing power consumption and fossil fuel use, increasing power efficiency to reduce cost, while achieving energy conservation and carbon reduction. In 2016, we have installed pipelines that gather effluents to the sewage treatment plant in coordination with government policy, and thereby reduce the burden on Earth’s environment.